For numerous companies, Industry 4.0 continues to represent the “next big thing” on which they are focusing their attention. It symbolizes the fourth wave of the industrial revolution, triggered and enabled by developments in information technology. Key components include automation, robotics, big data analytics, intelligent systems, virtualization, artificial intelligence (AI), machine learning, and the Internet of Things (IoT).

Many companies are still in the process of implementing this fourth revolution, but the next revolution is already in full swing – Industry 5.0. MORYX is equipped for this next stage of development and can help you expand Industry 4.0 and pave the way to Industry 5.0.

What means Industry 5.0?

The concept of Industry 5.0 is comparatively new. According to the European Union, Industry 5.0 represents “a vision of industry that goes beyond efficiency and productivity as the sole objectives and strengthens the role and contribution of industry to society”. It aims to put the well-being of workers at the center of the production process. Novel technologies are to be used to generate wealth beyond job creation and growth, while respecting planetary production limits. In essence, Industry 5.0 reflects a shift from a focus on pure economic value to a focus on social value. It is about a change in focus from wealth to well-being.

Industry 5.0 is based on three main areas: People-centeredness, resilience, and sustainability.

Industriy 5.0 with MORYX

Sustainability in production

Against the backdrop of the current widespread concern about climate change, the term sustainability hardly requires an introduction. Until now, the focus of corporate sustainability efforts has been mainly on reducing or limiting damage. Now, however, it is going beyond that. Instead of merely minimizing negative impacts, truly sustainable companies are focusing on maximizing their positive impacts. Thus, companies should be part of the solution, not part of the problem.

With MORYX, you can produce resource-efficiently. MORYX makes all data of your production processes accessible for analysis. This allows you to reduce material and energy consumption, eliminate waste and scrap, and replace harmful auxiliary materials.

Sustainability in production is promoted when, for example, it is largely paper-free. In addition, paper-based workflows are time-consuming and prone to errors. The use of MORYX can completely replace the consumption of paper in production halls. With this changeover, you avoid media discontinuities and make the processes in your production more up-to-date, faster and safer.

Resilience in production

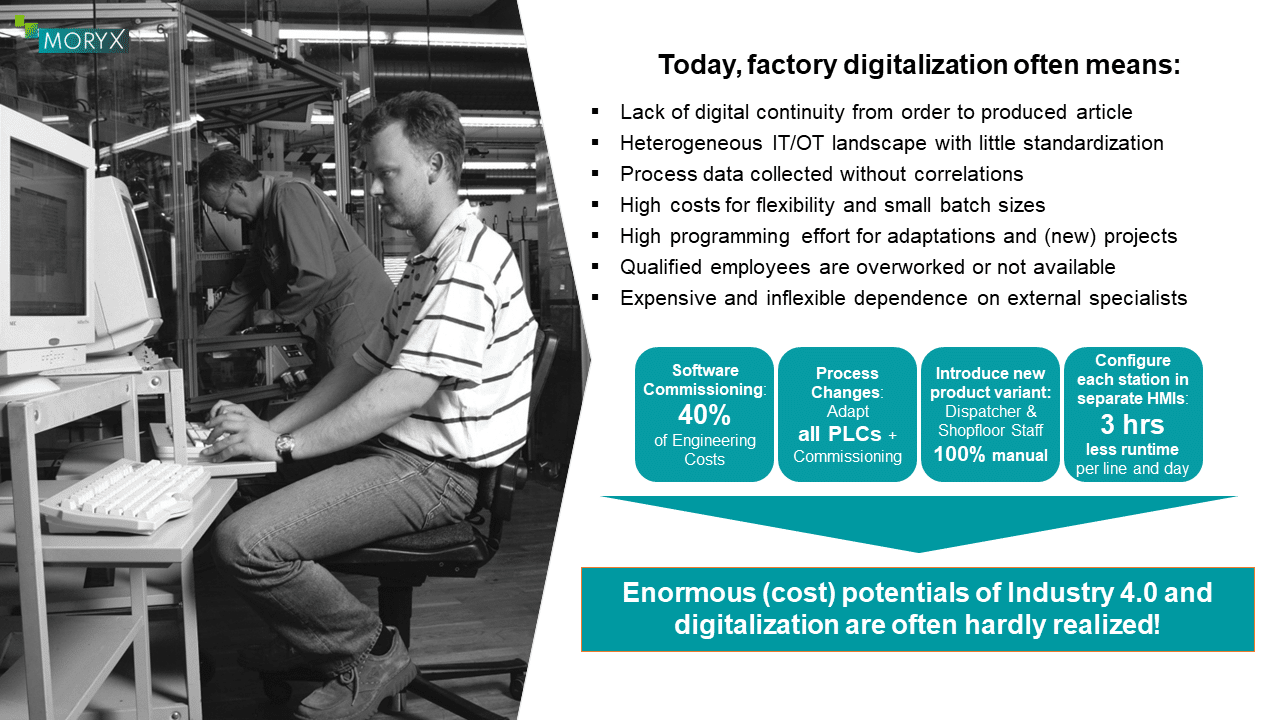

Adjustments during ongoing production are always associated with the risk of provoking downtime and unnecessarily long setup times. Downtime is simply not an option. Even if optimizations are known and theoretically feasible, adjustments are not implemented. The result: optimization potentials are not exploited.

Established digital solutions, which are supposed to address this very issue, offer a variety of approaches, but are rarely fully exploited. MES, PLC and other similar approaches have their advantages for different factory settings. However, none of these approaches ensures end-to-end control and data flows. The result is a fragmented digitalization that is not Industry 5.0 compliant, since, for example, the potential for avoiding waste is not leveraged across systems.

MORYX solves these weaknesses by flexibly integrating the open software platform optimally into any factory setting. No matter which product line, plant or machine. No matter which industry. No matter whether greenfield or brownfield scenario. No matter whether fully automated production or classic manual workstation.

People-centeredness in production

People-centeredness means putting people at the center. Talent, diversity and employee empowerment should be encouraged.

At MORYX, we have focused on ensuring that the interfaces are all consistent and easy to use. In this way, MORYX empowers production staff to model processes on their own, so that a specialist is not necessarily required. Due to the uniform interfaces, every employee can be used at every workstation. Thus, they can concentrate on creating added value and do not have to deal with differently operable interfaces again and again.

Since 2019, MORYX has also been used as an interactive application. In this case, a skilled worker is notified of problems at the plant via his smartwatch. MORYX records machine conditions at the plant and associated messages such as errors, warnings and general information in real time. If problems are detected at the plant, a support request is sent to the plant personnel. This gives the operator maximum flexibility to respond quickly to challenging machine conditions.

Conclusion

Industry 5.0 promotes direct collaboration between humans and “intelligent” machines. Digitization is intended to help people work faster and better, but as far as possible the focus should be on people and their well-being. The aim is to enable people and promote their talents, to design work processes in such a way that the machine supports people physically and mentally. This is exactly the goal we would like to implement with MORYX in your production!

Do you have further questions about Industry 5.0 or MORYX? Then please feel free to write to us!

0 Comments