Digital Manufacturing with MORYX

Established and industry-proven. Open to customization.

“With the platform, we can semantically model machine parameters per article and variant. As a result, we generate 8% fewer process errors and save 50% time per new variant.”

Thomas Fuchs, Software Engineer at MORYX Industry

Digital factory conceived in concrete terms, implemented across the board

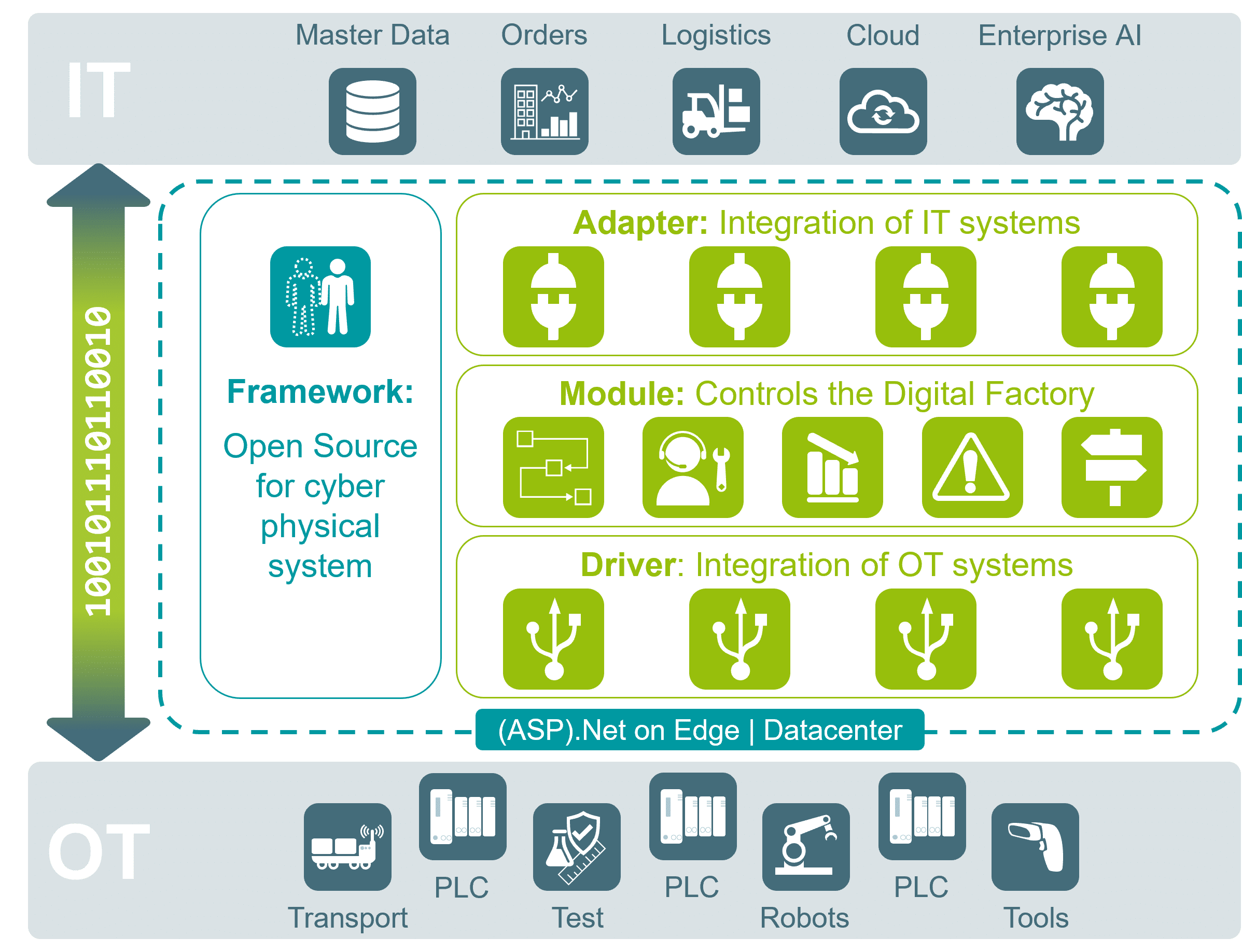

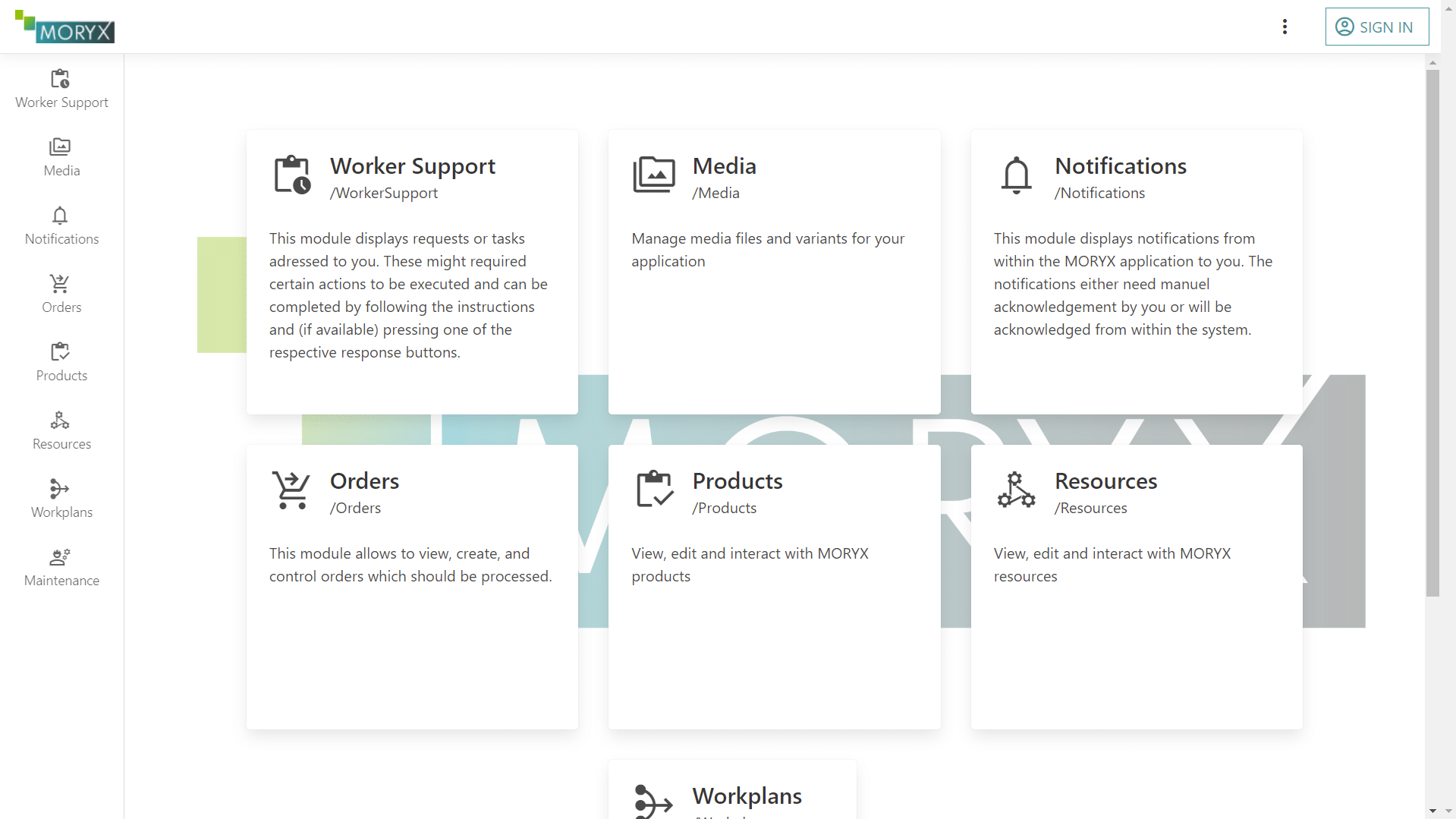

MORYX is an open software platform for all work steps in your company. It is the only platform on the market that allows you to actively intervene in manufacturing and reconfigure all machines centrally – without any PLC programming knowledge. Its highly integrated architecture links all data from processes, products and OT. New orders and master data can be imported automatically to start production immediately. A visual worker assistant supports the staff, and digital twins can be created in a data-consistent manner.

Challenges of ever-changing factory conditions

How to stay in control of manufacturing processes?

With MORYX, you can actively control all processes and intervene yourself when changes are made. A centralize worker assistence enables skilled workers to configure machine parameters without programming knowledge. Optimizations are possible in real time and not only after long production failures and high reject rates. Production keeps running.

The platform solves the problems that are common in engineering, commissioning and operations. At the same time, it is open to the integration of other digitization tools such as software, different machines and manufacturers. Everything related to manufacturing jobs is embedded in MORYX and not distributed in different PLC systems.

Components

MORYX is constantly evolving. The following components, drivers and modules are only a selection from our wide range of solutions and are constantly being expanded. If your system landscape contains other technologies than mentioned here, please contact us!

At a glance

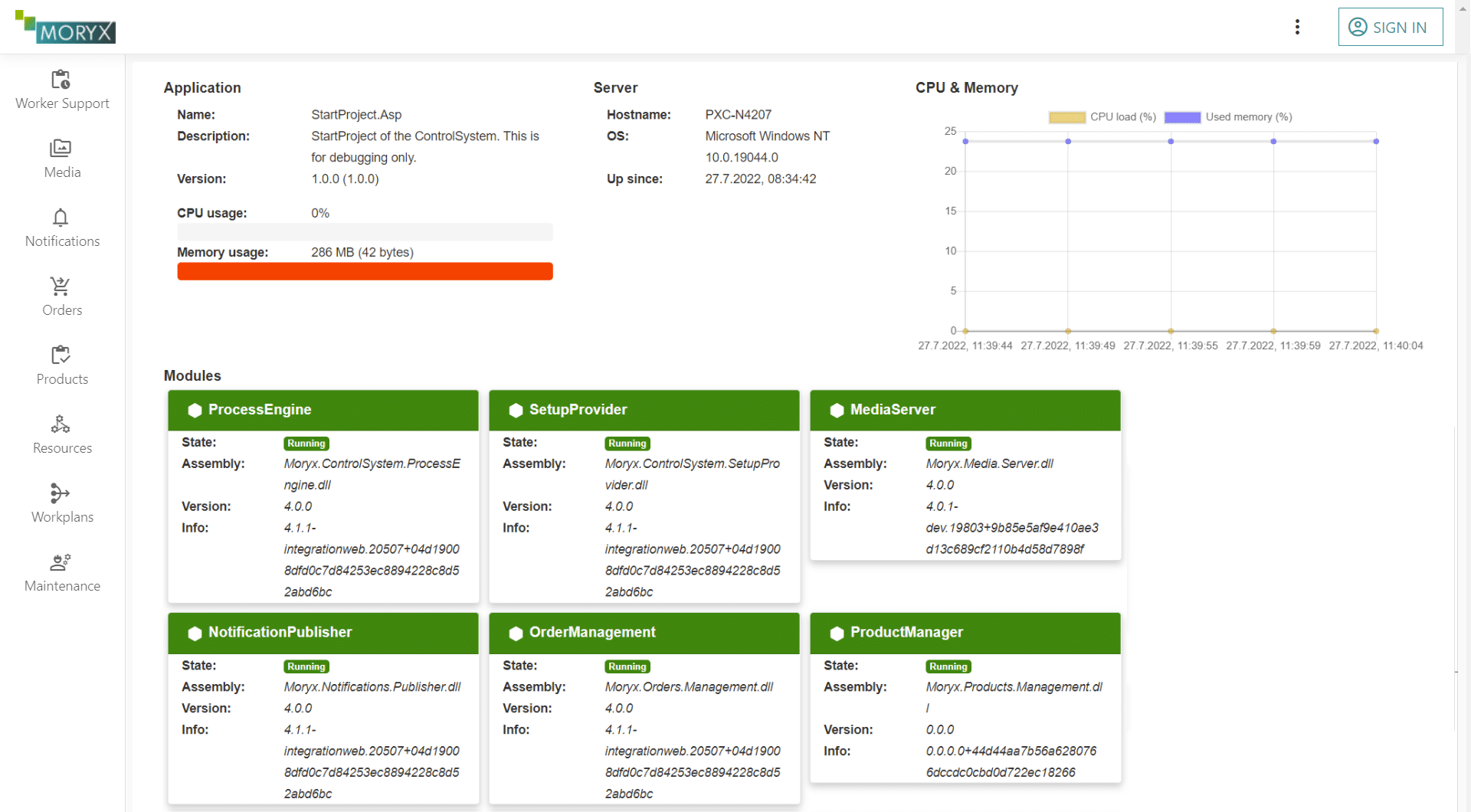

Open Source Framework

MORYX provides the first Open Source Framework to model devices and their relationships in the factory. Within the framework, the individual parts of the plant are assembled into a complete system. Applications can be flexibly assembled from modules, and the open-source approach ensures the compatibility of the components. This allows you to continuously develop the system for future requirements!

Control of the digital factory

Modules

With MORYX you rely on a solution that goes through regression testing and is continuously developed. Changes to the code are immediately tested and described before they are added to our modules. This ensures the highest possible stability and security. Configurations are possible via user-friendly interfaces and from a central location.

Processes

Execute and control modeled processes

Process Data

Collect and manage Process Data

Setup

Derive necessary setup operations and generate setup routings

Workplans

Create, delete, model and version routings

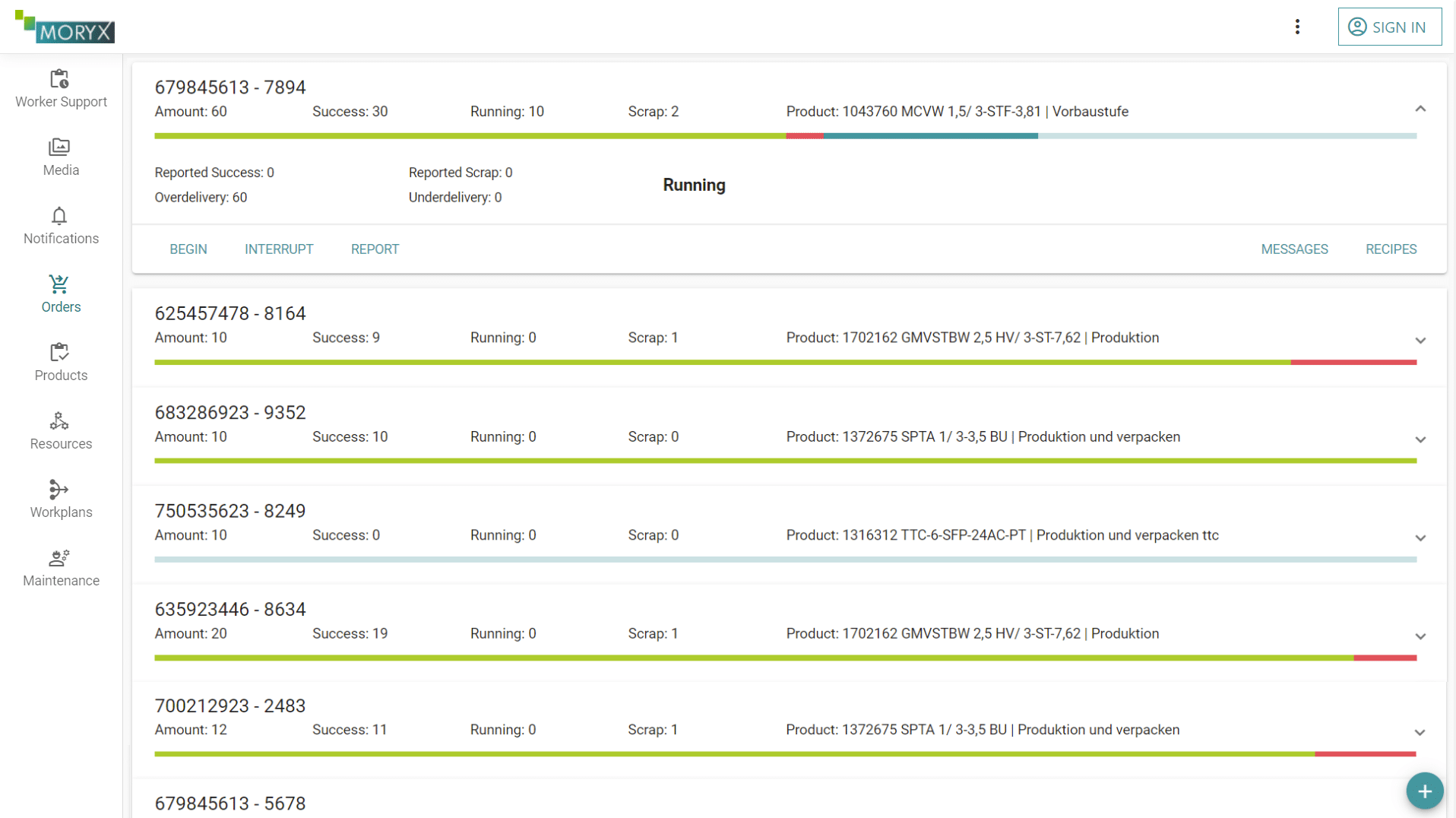

Orders

Create, delete, start, stop, interrupt and confirm orders

Reports

View and confirm current messages, analyze historical reports

Worker Support

Display digital media configurable to support manual work steps

Transport

Coordinate and control component and material transport

Production Media

Upload, import, delete and view available digital media

Analytics

View dashboards with metrics on historical data and trends

Integration of IT systems

Adapters

MORYX adapters ensure the digital integration of IT systems such as ERP or master data. A MORYX adapter realizes the communication to an IT system and includes all necessary data structures and protocols. With the help of this clear responsibility, the MORYX adapters can be reused as often as required – independent of the application and the drivers used and with consistently high quality.

Influx DB

Data export to InfluxDB data bases

MQTT Cloud

Connection to the MQTT Cloud

Spreadsheets

Data exports to formats such as MS Excel

SAP ERP Synch

Connection to the SAP ERP

Integration of OT Systems

Drivers

MORYX drivers bundle the data structures and communication types per device type and manufacturer. They guarantee manageability of the heterogeneity and diversity of PLC systems in production devices. Thanks to the modular MORYX architecture, you can easily maintain, update and reuse MORYX drivers in applications as often as you like and combine them with each other.

MQTT Protocol

Communication with OT devices using MQTT protocol

TRUMPF TLV Protocol

Communication with OT devices by means of TLV protocol of the TRUMPF company

Cognex Scanner

Communication with scanners from the Cognex company

Datalogic Scanner

Communication with scanners from the Datalogic company

Standardization and Reuse

Lower Engineering Costs

Reuse of Software

“Simply configure, instead of elaborate programming” is the guiding goal of MORYX. With this attitude you save about 50% of software development costs and 60% of commissioning costs for bug fixes.

Digital Integration and Flexibility

Instead of rigidly chaining stations in process control and plant design by PLC, making adjustments difficult, all data migrates to the central MORYX Platform. You gain system independence through sustainable integration – whether in heterogeneous PLC, ERP or MES environments.

Virtual testing and data optimization

Accelerated commissioning

Virtual Commissioning

The commissioning of new machines or plants can take up to 25% of the total lead time of a project. By creating Digital Twins, this time can be significantly reduced.

Uniform Database

With MORYX, you maintain changes directly on the line and can clean up errors – always with the security of a change history behind you. Data consistency and transparency are ensured at all times.

Intervene Actively, stay productive

More efficient operational business

Overall picture on the production

With the platform, you have an overview of the status of your orders at all times and are immediately informed if there is a malfunction in the plant. Both the number of successfully produced pieces and rejects are clearly displayed. You can optimize processes in real time and during production. The plant never has to stand still!

Active Intervention

Production employees can independently create products or orders and actively control and adjust processes. This actively optimizes the entire process and reduces rejects.

MORYX works for all industires.

Elektronics

Mechanical and Plant Engineering

Energy

Trade

Wood & Furniture

Energy Production, Storage and Infrastructure

Let's disrupt manufacturing

Wenn Sie weitere Fragen haben, können Sie uns gerne kontaktieren. Gemeinsam werden wir Ihr Projekt realisieren!