Advantages for the CEO

Future Security through Flexibility

With MORYX, you set up your production development and manufacturing sustainably and future-proof. You can train new personnel quickly and remain capable of production even in the event of a shortage of skilled workers. MORYX ensures transparency and traceability across all processes. The platform can be flexibly expanded and is open for future developments. This allows your company to grow securely and steadily.

Highest efficiency in production

Automatic start of orders

- 3 hours more runtime – per line and day

- Machine parameters are semantically modeled per article and variant

- 8% less process errors

- 50% time saving per new variant

- Optimizations possible in real time – no long production errors with high reject rates

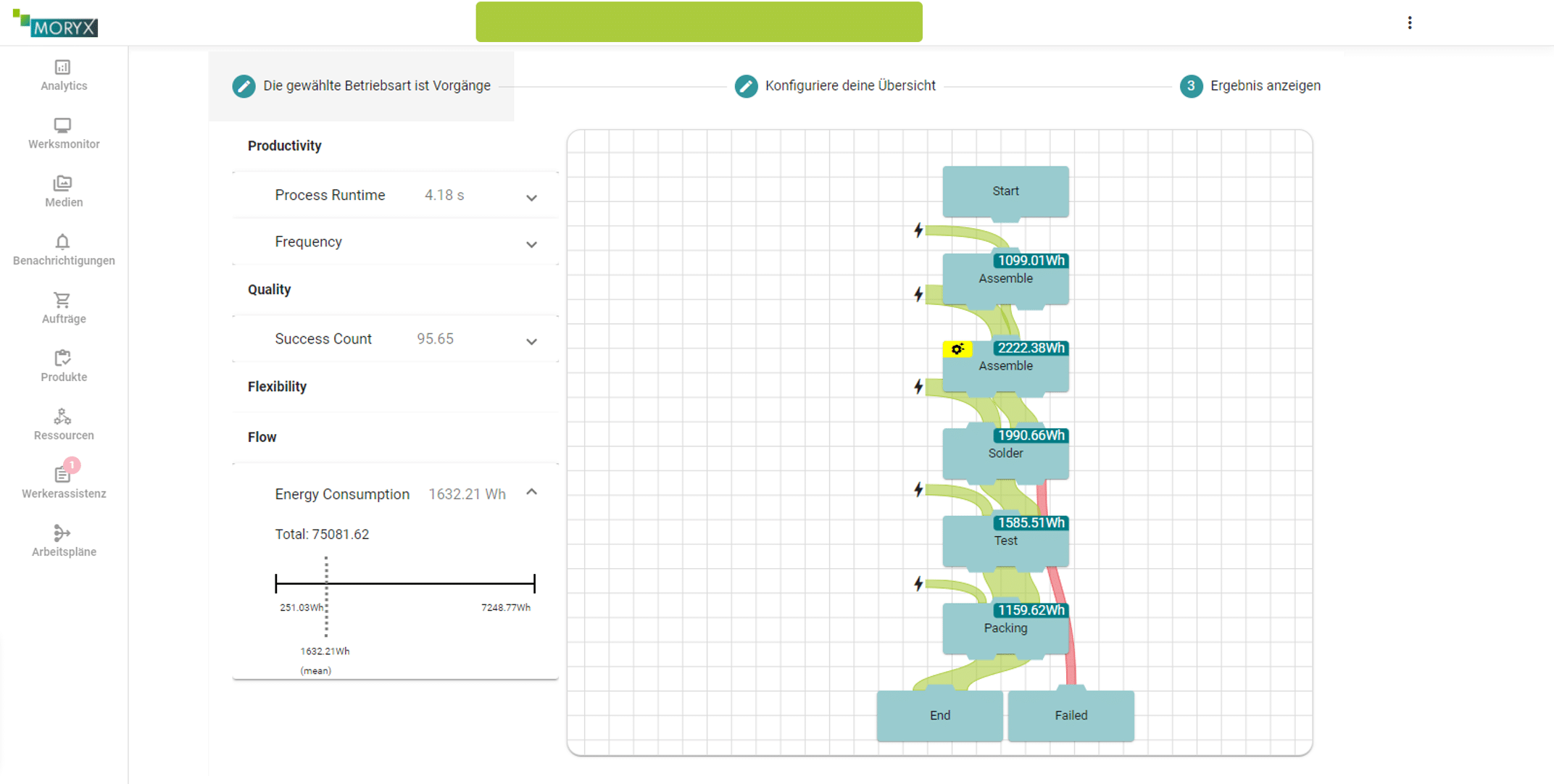

At a glance

Your advantages

50 % less costs

Through preconfigured software that can be reused

90 % reduced downtime

Through adaptive control of backup cells and fault messages

5 % more capacity utilization

Through modeling of producible article spectrum per line

3 hours more runtime

Per line and day due to automatic start of jobs

10 % shorter throughput time

Due to improved first-pass yield and reprocessing close to the process

50 % less time per variant

Through semantic modeling of machine parameters per article (variant)

Higher degree of digitalization

Manage complexity

With MORYX, you simplify the work of everyone involved because you digitalize the factory end-to-end. Your employees can change processes independently and in an understandable programming environment while the plant continues to run:

- Workers can respond quickly and flexibly even to complex changes.

- You need fewer skilled personnel and can overcome manufacturing challenges with tools such as a worker assistant. For example, work processes can be predefined step by step on a graphical interface, allowing new employees to quickly learn the ropes.

More efficiency for your production

Reduce engineering costs

Classically, you test and optimize real plants to ensure the desired performance. You test functions, simulate critical states and invest a lot of effort in rework. With MORYX, you save time and money because plants can be planned virtually before they are put into operation. The platform simplifies complex tasks, allowing you to eliminate the need for highly skilled personnel in many areas – especially PLC programming. Instead of writing new code, your employees configure the machines centrally via MORYX. This significantly reduces engineering expenses. With the platform, you also prevent plant downtimes and reduce the production of rejects.

Moryx in use

Phoenix Contact Device Connectors Factory

The Phoenix Contact Device Connectors Factory produces small parts for PCB connectors that are transported to and from production lines. MORYX…

- integrates the ERP, the automated guided vehicles, and the manufacturing technology into the plant technology.

- ensures visibility into the status of ordered material and loading equipment (LHM). Factory personnel can request the required material per production order manually or automatically. It is also possible to request the LHM and have it picked up.

- offers transparency at any time for each loading equipment on material information, production order and transfer.

We find a solution that suits you

Feel free to contact us if you have any further questions. Together we will realize your project!