Advantages for Production experts

Keep your production running

As a Production Expert, you have to ensure your factory never stand still. With MORYX you can actively intervene in the factory control yourself. You become independent of PLC specialists. This enables you to meet delivery times, reduce rejects and avoid material bottlenecks. Even small batch sizes and customized products can be produced efficiently with MORYX.

Data-protected transparency and optimization

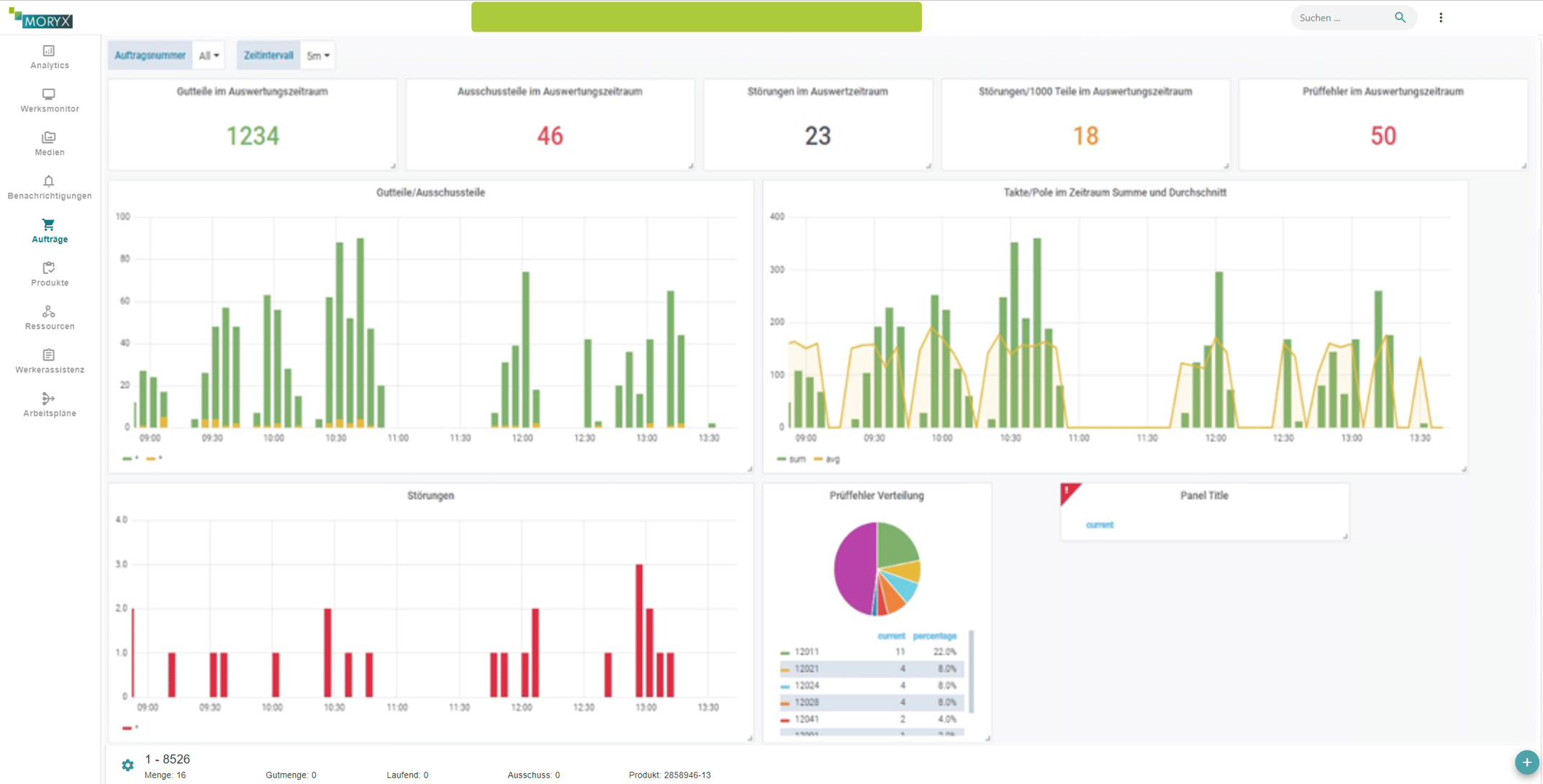

Uniform data interface

- MORYX provides a unified interface to data from process, product and OT through highly integrated architecture.

- Various analysis tools and databases can dock to the open interface.

- MORYX dashboards use this interface and are individually configurable

- Artificial Intelligence use cases obtain training and live data via this interface

At a glance

Your advantages

Changeover time under 1 minute

Through parallel production & automatic article management

90 % reduced standstill

Through adaptive control of backup cells

3 hours more runtime

Per line and day due to automatic start of jobs

5 % more capacity utilization

Through modeling of producible article spectrum per line

8% fewer process errors

Through semantic modeling of machine parameters per article (variant)

10 % shorter lead time

Including reduced scrap due to optimized first-pass yield

Forget about standstills

Fasten reprogramming and retrofitting

MORYX enables you to reprogram and convert lines and machines in one fell swoop. Instead of adapting each PLC system individually, you can convert all systems centrally via the platform. If, for example, you have a new product variant manufactured or want to adapt an article to legal requirements, you maintain these changes with MORYX – production continues during this time. You use a simple programming environment for this, without having to have PLC expertise. In this way, you resolve dependencies of the individual process steps and systems, prevent downtimes and save time and costs.

Strong with changes

Master chanceover processes easily

MORYX fits perfectly in existing structures – if you want. You can use already existing systems for variance, place the MORYX framework on top and configure necessary adjustments. This significantly reduces the effort for conversions as well as reprogramming. Even small batch sizes can be mastered, because retooling of the machines is possible without production downtime. By being able to reuse MORYX software modules for new functions and create digital twins, rebuilt plants can be put into operation faster and more flexibly. Data continuity from IT to production is guaranteed and makes any change manageable.

Moryx in Use

TRABTECH Factory at Phoenix Contact

The TRABTECH factory in Phoenix Contact produces products for surge protection. The TERMITRAB complete products are assembled in the plant, with 280 product variants possible from 3 product families. The basic assembly process consists of the following steps: board assembly, soldering, labeling, connector setting, testing, packaging and labeling. There is a high variance in product and processes per order with highly fluctuating lot sizes.

With MORYX…

- There is no downtime during job changes.

- The scrap rate is minimized by reprocessing the scrap and finishing it completely.

- First pass yield (first pass without defects) is maximized. At the same time, manual operations can be gradually replaced by automation.

Let’s elevate your production to the next level

Feel free to contact us if you have any further questions. Together we will realize your project!