The Digital Factory is a vision of the future that more and more companies are striving for. It promises higher efficiency, lower costs and better quality in production. But what is the easiest way to follow this path to the Digital Factory? One possibility is offered by the open platform MORYX.

In recent years, digialization has made enormous progress not only in industry, but in almost all areas of life. Even the production of goods and products has not been spared from this development and has evolved. However, in almost every digialization project, cuts have to be made in the functions that can be used productively, or the originally planned duration of the project is extended. But how can you realize the ideal of a Digital Factory? In this article, we would like to introduce you to the basics of the digital Factory and show you how MORYX, a factory automation software solution, can help.

Digialization of the factory

In our personal lives, we have become accustomed to the fact that going digital has become easy and affordable. Home automation has become a do-it-yourself task today and complete processes can be defined without programming knowledge. In production facilities, however, things often still look quite different. MORYX now proves that industrial lasers, robots and test cells can also be quickly integrated into manufacturing processes and that production systems can be integrated as flexibly and easily as DIY.

But what exactly is a Digital Factory? The Digital Factory is a concept that refers to the use of advanced technology and intelligent software in production. In a Digital Factory, traditional production methods are replaced with automated and computerized processes to increase efficiency and accuracy and reduce labor costs.

A Digital Factory is typically characterized by the use of data and analytics to optimize production processes and minimize process errors. The use of networked technology and sensors makes it possible to collect and analyze real-time data to make fast and accurate production decisions.

How can MORYX help?

In today’s increasingly digitized and automated industry, it’s more important than ever to rely on innovative solutions to optimize your processes and reduce costs. This is exactly where MORYX comes in.

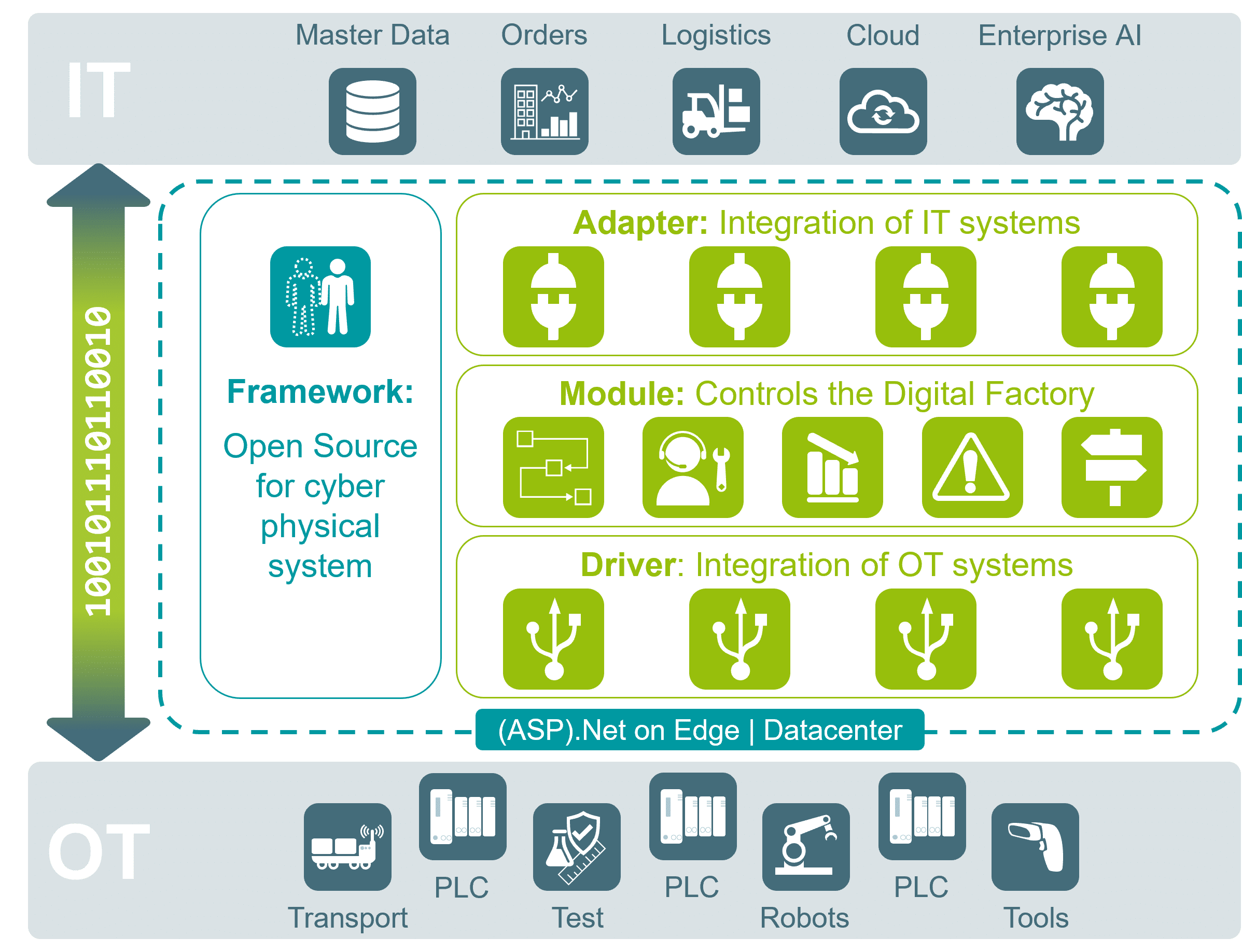

The name is made up of the words “Modular”, “Factory” and an “X”, which stands for “Cross Industry”. MORYX abstracts and integrates heterogeneous IT and OT systems to centralize and reuse logic and algorithms from digialization applications. MORYX thus aims to enable product- and process-neutral control and regulation of plants. This means that controllers from different manufacturers can also be easily integrated into overall plants. This means that you are able to optimize your production processes without having to worry about new systems not being compatible with existing systems.

Process and integration

The path to the Digital Factory with MORYX starts with the analysis of the existing production. Here, the workflows and processes are examined in detail and possible weak points are identified. These can be, for example, inefficient workflows or bottlenecks in production.

Based on this analysis, a concept for the Digital Factory is then created. The company’s goals are also taken into account here. For example, a higher production volume, better quality or a reduction in costs can be targeted.

In the next step, MORYX is implemented at your company, customized and adapted to the existing production. Your employees can concentrate on the essential tasks while MORYX controls the production processes. The quality of the products can also be improved, as errors can be detected and corrected more quickly.

Your advantages for your Digital Factory with the open platform MORYX

One of the advantages of MORYX is the flexibility of the software. The open source framework can be used to model devices and their relationships. Within this framework, the individual parts of the plant are assembled into a complete system. The open source approach ensures comptability among the components and also allows the system to be continuously developed for future requirements. With MORYX, you can set up your factory in a sustainable and future-proof way, and at the same time increase efficiency and productivity, which ultimately also leads to a reduction in costs.

Conclusion

Digialization and automation of production processes are important steps for factories to stay competitive, optimize production processes and position themselves for the future. However, digialization can also be challenging as it often requires a significant time investment.

MORYX offers a solution to these challenges by providing a flexible and customizable platform for the automation and digialization of production processes. With MORYX, factories can optimize their production processes and increase efficiency to stay competitive and grow their business.

0 Comments